Trusted company that deals in quality-made products

Showroom

Release Films are engineered to work smoothly and to last long on the field. Being very simple to apply and providing a clear and tangible coverage they show great resistance to bubbling and peeling. Applicable to various types of surfaces and contexts, delivering consistent and, at the same time, durable performance.

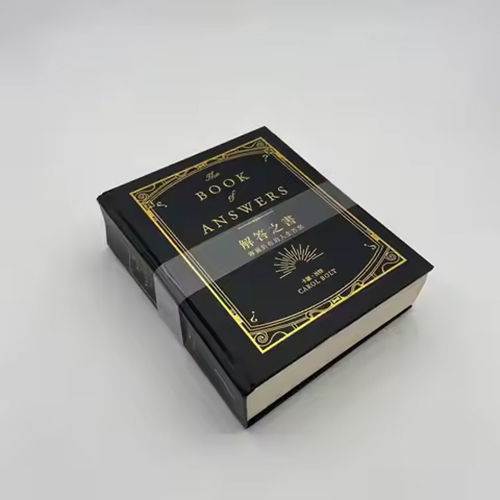

Fastener Collating Tapes offer the easiest way of consolidating and fastening materials in one system. Because of their high degree of tackiness, they are ideal for industrial and office purposes, sealing documents and packages tightly.

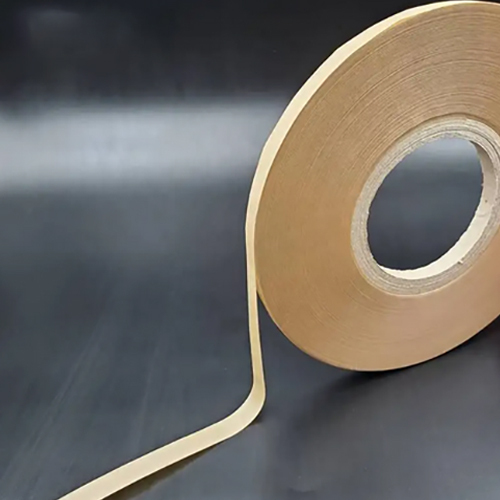

Banding Tapes For Packaging are ideal backing for all your packaging demands. They come in different sizes and thicknesses and can be used for a wide range of uses in packaging and can be used either by hand or by mechanical means.

Carton Angle Pasting Tapes enable guarantees on sealing and pasting of the corner of a package. These are durable and easy to use, come in good quality adhesive, and additionally come in a number of sizes that make them ideal for business or home use.

Protective Film rolls have the function of protecting furniture, floorings, electronic contacts, etc. from scratches, dust, and damage. These films are easy to apply and they are available in different sizes and types to meet various needs and ensure that they offer protection for a long duration.

PI Tapes are designed for performance and durability in view of the expected compressor demands. These include; Their polyimide film makes these tapes fully resistant to temperatures and chemicals hence best for electronics and automotive industries.

Our PP Strapping Bands give you strong support for all your packaging projects. These bands are characterized by their great strength thus making them ideal where breakage resistance is a major concern in bundled items. They come in different sizes as well as different thicknesses and this makes them versatile in packaging.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese