Welcome to Our Comapny -

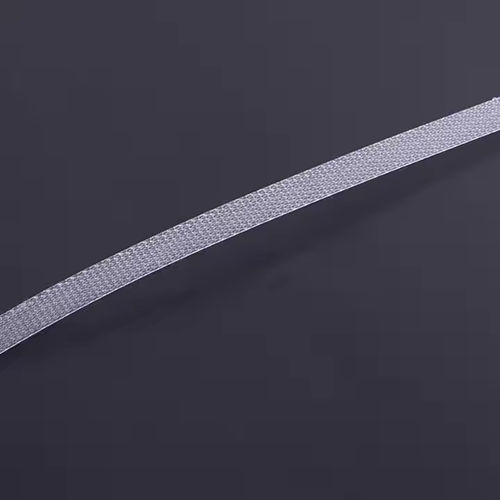

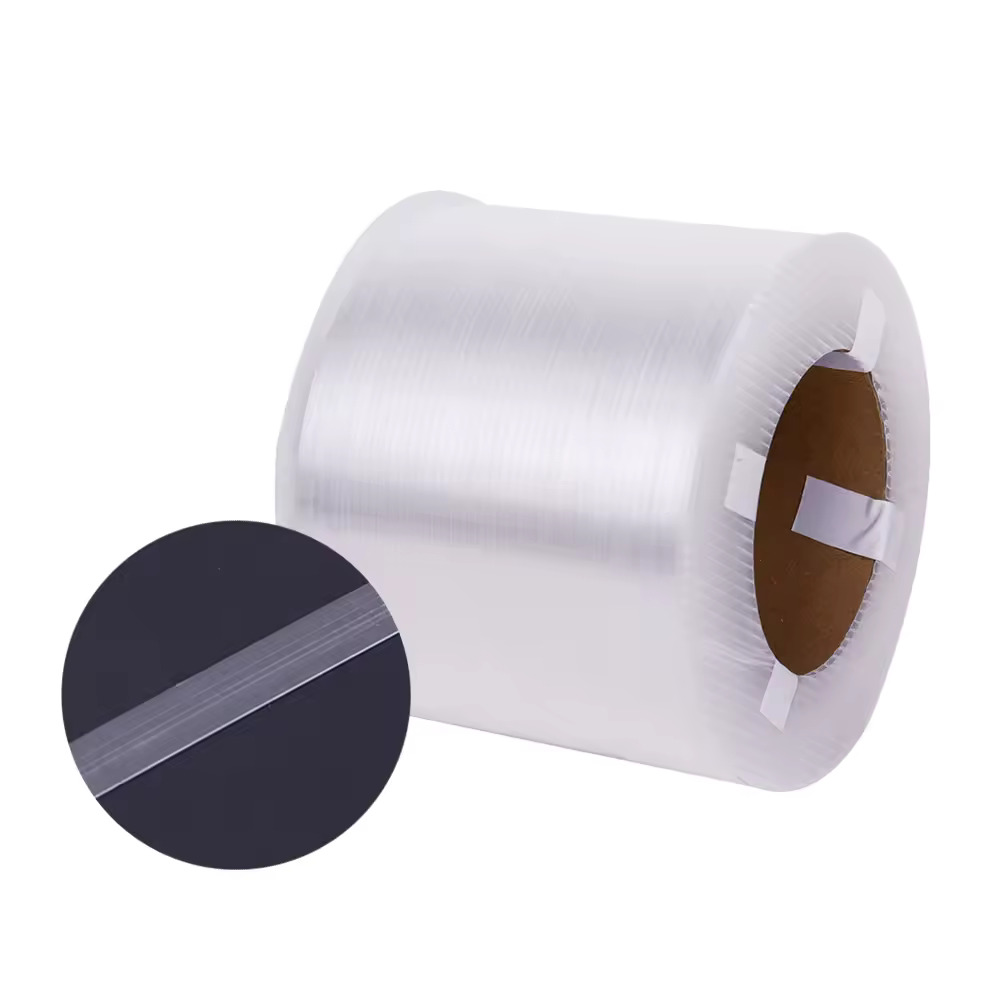

8mm Width Clean PP Strapping Bands

2.80 - 3.50 USD ($)/Roll

Product Details:

- Product Type Other

- Material BOPP

- Type Strapping Band

- Style Machine Grade/Hand Grade

- Packing Format Roll

- Hardness Soft

- Tensile Strength 60-150 kgf (approximate range for PP Strapping)

- Click to View more

X

8mm Width Clean PP Strapping Bands Price And Quantity

- 5000 Roll

- 2.80 - 3.50 USD ($)/Roll

8mm Width Clean PP Strapping Bands Product Specifications

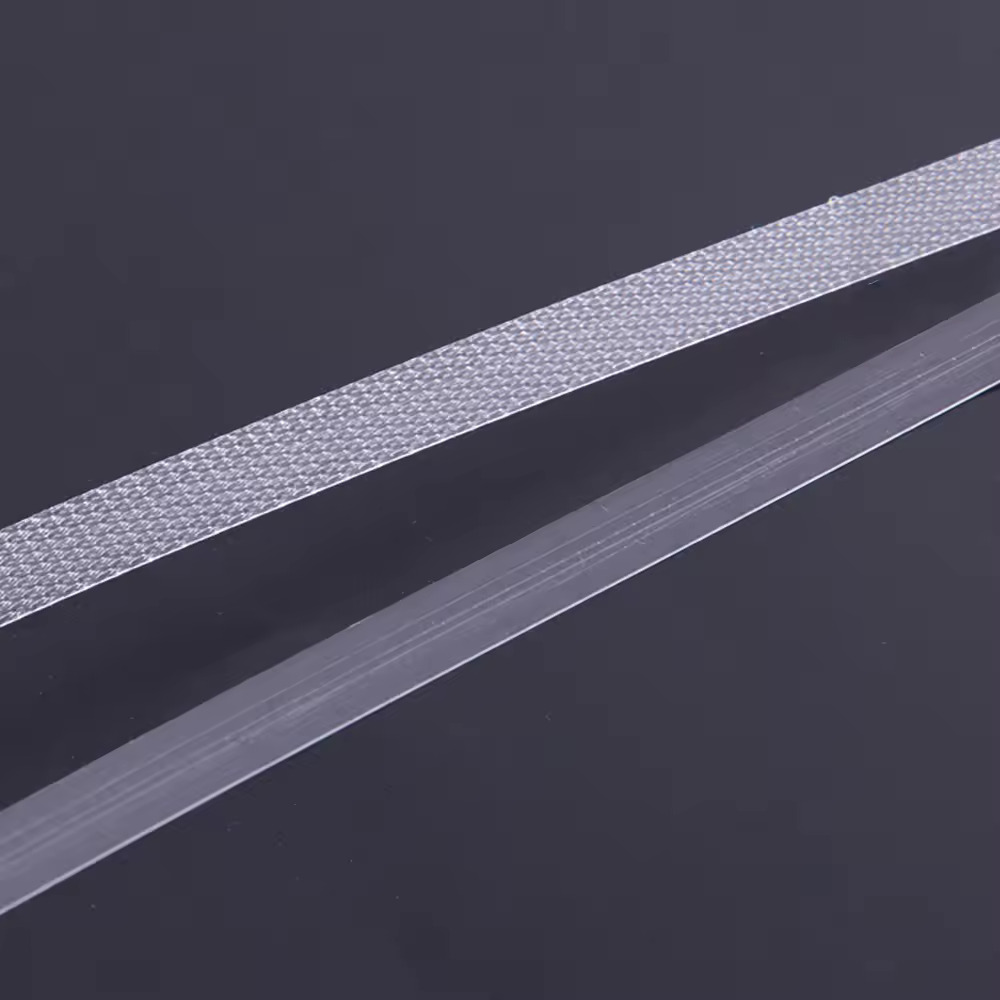

- Foggy

- Soft

- 8mm Width

- Machine Grade/Hand Grade

- Other

- 60-150 kgf (approximate range for PP Strapping)

- Roll

- Strapping Band

- BOPP

8mm Width Clean PP Strapping Bands Trade Information

- 100000 Roll Per Month

- 21 Days

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

Banding Tapes

- All Banding Machine Compatible

- Extensive Customization

- Eco-Friendly & Cost Efficient Packaging Solution

- Ease of Unpacking

- Premium Print Quality

- Crisply Cut Edges

- Application In Diverse Range Of Items

- Superior Adhesion

- Merchandize Image Enhancement & Sales Boost

- Safety Enhancement Against Item Damages

- Proper Transport Packaging That Protects Goods While In Transit

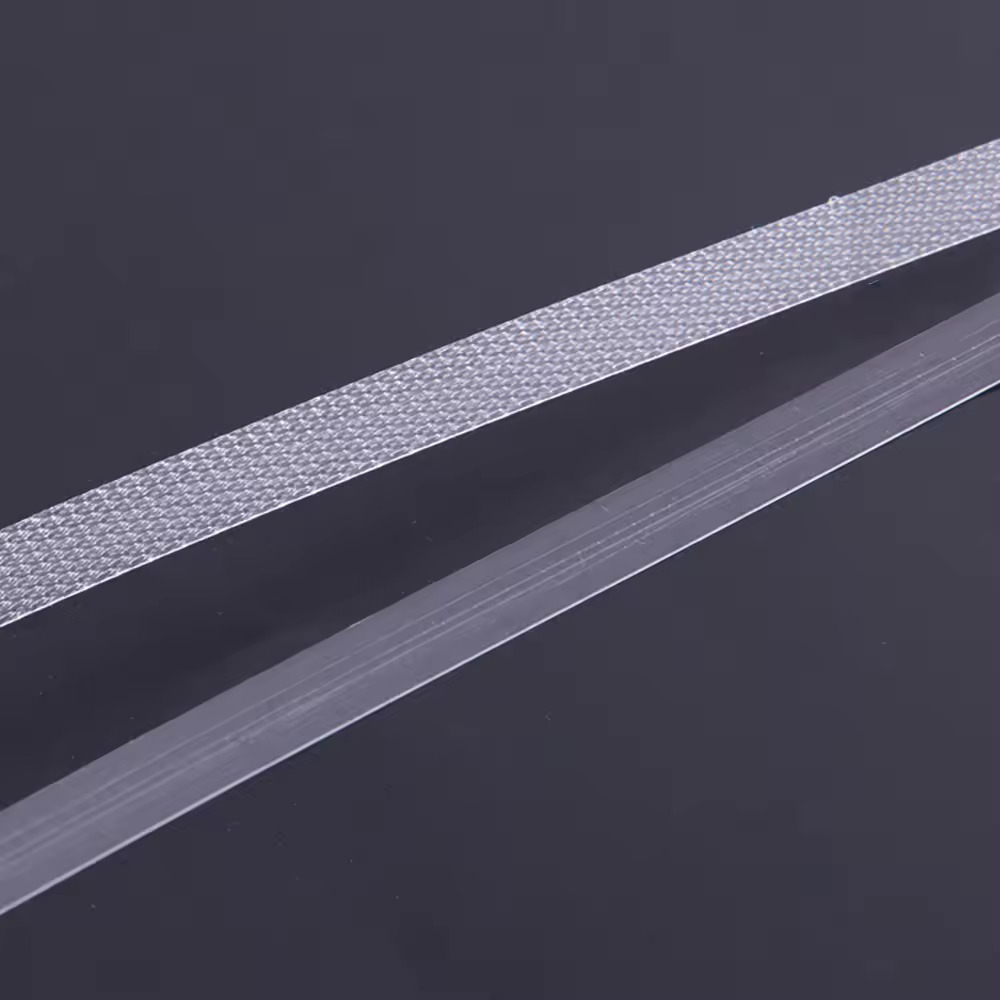

Banding Film

Film made of high-quality BOPP coated on one side with a layer of hot-melt adhesive. Banding films with different load bearing capacity, elasticity, and tear-resistance. Films can be printed with graphic images in outstanding quality for a maximum advertising effect.

FAQ:

Q: What types of strapping are there?

A: Banding Film, Banding Paper, Antistatic Banding Film

Q: Can you accommodate special customizations?

A: Yes, as long as its within our capability, like for example the minimum width we have available is 20mm. Depending on the customization, the price may vary.

Q: Where can strapping be applied?

A: Strapping is highly suitable and environmentally friendly for applications like biscuit gift boxes, food packaging, bundling banknotes, boxed medicine packs, bundled towels, tea bags, pencils, books, newspapers, and vegetables, all meeting international standards.

Superior Performance for Packaging

Our PP strapping bands offer efficient and secure fastening for carton boxes and various packaging applications. Made with high-quality BOPP, the bands provide consistent breaking strength, moderate UV and heat resistance, and limited stretch for stabilized loads. They suit both machine-grade and hand-grade usage, ensuring flexibility in your strapping process.

Reliable, Clean, and Customizable

Featuring a smooth and clean finish, these strapping bands are ideal for environments where aesthetics matter. Their foggy color and odorless nature add to the overall presentation. Custom printing is available upon request, letting you reinforce branding or essential details directly on the strap.

FAQs of 8mm Width Clean PP Strapping Bands:

Q: What types of packaging applications are suitable for 8mm Clean PP Strapping Bands?

A: These strapping bands are commonly used for securing carton boxes, bundling products, and general packaging tasks. Their machine-grade and hand-grade compatibility makes them suitable for both automatic strapping machines and manual strapping tools.Q: How is the strapping band applied, and can it be used with both manual and machine tools?

A: The 8mm PP strapping band can be applied using manual strapping tools or automated strapping machines, thanks to its flexible design and consistent roll format. They fit a standard 200 mm core diameter, facilitating easy handling and installation.Q: What are the benefits of using this PP strapping band over other materials?

A: Benefits include reliable breaking strength (60150 kg), moisture resistance, moderate heat and UV stability, and soft hardness for gentle strapping. Additionally, the foggy color and smooth surface provide a clean look, while recyclability supports sustainability.Q: Can I request custom printing or branding on the strapping bands?

A: Yes, printing options are available upon request, allowing you to display your company logo or product information on the bands for enhanced brand visibility and identification.Q: Are these bands recyclable and safe for various environments?

A: The strapping bands are made from BOPP material and are fully recyclable. Being odorless and clean-finished, they are suitable for both storage and transit in diverse packing environments.Q: When is the ideal time to use these PP strapping bands?

A: These bands are perfect for use during packaging, shipping preparations, or whenever strong, secure bundling of boxes and goods is required, especially in logistics, warehouses, and distribution centers.Q: Where are these strapping bands manufactured, and how can I ensure consistent quality?

A: The strapping bands are manufactured in Taiwan under strict quality controls, ensuring uniformity in width, thickness, and breaking strength across all rolls. Reliable supply and minimum order quantities support large-scale packaging operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese